Introduction:

Industrial complexes are dynamic environments where efficient transportation plays a vital role in productivity and operational success. In recent years, golf cart batteries have emerged as a game-changer, transforming the way industrial complexes function. This article explores the reasons why industrial complexes should embrace golf cart batteries and delves into their implementation across six key areas.

Enhanced Mobility and Efficiency:

Golf cart batteries offer a versatile and efficient mode of transportation within industrial complexes. Their compact size and maneuverability allow for easy navigation through narrow aisles and crowded workspaces, facilitating seamless movement of personnel, equipment, and materials. This enhanced mobility translates into improved efficiency and productivity.

Example: Amazon’s fulfillment centers have integrated golf cart batteries into their operations to optimize transportation efficiency. The compact electric carts enable employees to swiftly navigate the expansive warehouses, accelerating the order fulfillment process.

Eco-Friendly and Sustainable Solution:

Golf cart batteries provide industrial complexes with an eco-friendly and sustainable transportation alternative. These batteries produce zero emissions and have a significantly reduced carbon footprint compared to traditional fossil fuel-powered vehicles. By utilizing electric golf carts, industrial complexes can contribute to environmental preservation and align with sustainability goals.

Example: In their commitment to sustainability, Toyota Motor Manufacturing in Kentucky implemented golf cart batteries to transport employees within their vast production facilities. This initiative has not only reduced carbon emissions but has also enhanced the company’s reputation as an environmentally responsible manufacturing facility.

Safety and Noise Reduction:

Utilizing golf cart batteries promotes safety and reduces noise pollution within industrial complexes. Electric carts operate silently, eliminating the noise generated by traditional vehicles, creating a less distracting and safer work environment. Additionally, the absence of exhaust emissions contributes to improved air quality, minimizing health hazards for employees.

Example: General Motors incorporated golf cart batteries into their assembly plants, ensuring a quieter and safer work atmosphere. The reduced noise levels have improved employee focus and helped enhance overall productivity in the production processes.

Cost-Effectiveness and Maintenance Efficiency:

Golf cart batteries offer cost-effective and efficient operations within industrial complexes. These batteries require less maintenance compared to internal combustion engine vehicles, resulting in reduced downtime and lower maintenance expenses. Moreover, electric golf carts have fewer moving parts, minimizing the risk of mechanical failures.

Example: The Volkswagen factory in Wolfsburg, Germany, adopted golf cart batteries for internal transportation. This shift not only reduced maintenance costs but also allowed maintenance staff to focus on critical tasks, optimizing operational efficiency.

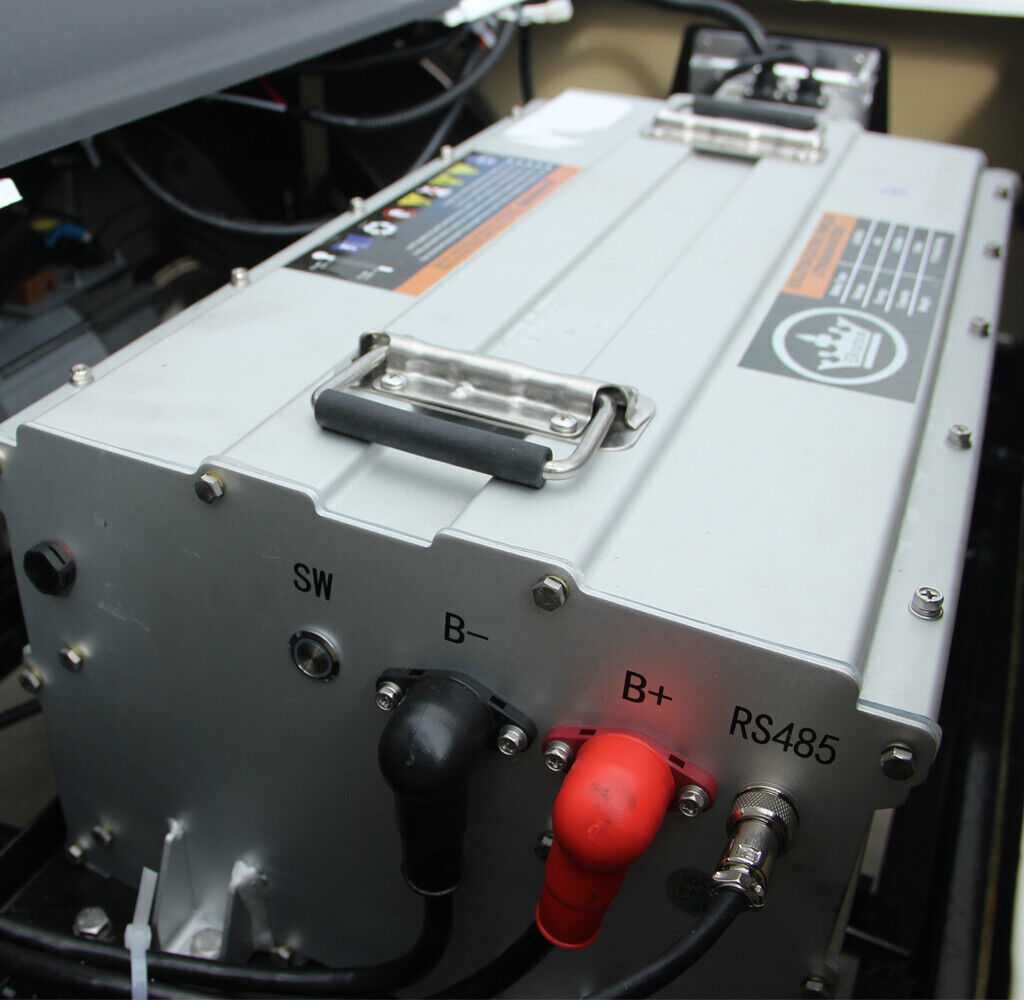

Integration with Renewable Energy:

Golf cart batteries can seamlessly integrate with renewable energy sources, such as solar panels or wind turbines, within industrial complexes. Excess renewable energy generated during peak production periods can be stored in the batteries, ensuring its efficient utilization during periods of high demand or power outages.

Example: Tesla Gigafactory in Nevada utilizes golf cart batteries to store excess solar energy generated by their extensive solar panel array. This stored energy is used to power the electric fleet of golf carts, reducing reliance on the grid and promoting renewable energy integration.

Customization and Adaptability:

Golf cart batteries offer customization and adaptability to fit the unique needs of industrial complexes. These batteries can be modified to include additional features such as cargo space, towing capabilities, or specialized equipment racks. This flexibility allows for seamless integration into various industrial processes, facilitating the transportation of specific tools and materials.

Example: In the aerospace industry, Boeing implemented golf cart batteries customized with specialized equipment racks to transport delicate and sensitive components within their manufacturing facilities. This customization ensures the safe and efficient movement of critical parts, streamlining production processes.

Conclusion:

The utilization of golf cart batteries within industrial complexes holds immense potential for driving efficiency, sustainability, and safety. From enhanced mobility and reduced environmental impact to cost savings and adaptability, the advantages are significant. By exploring successful implementations across industries, industrial complexes can harness the full potential of golf cart batteries, transforming their operations into a more efficient, eco-friendly, and productive environment.